Plastic packaging are derived from fossil fuels and usually disposed of immediately. As they are durable, light and cheap, they have long been popular materials to make wrappers and containers. Yet, little plastics in packaging are being recycled or reusable by design, creating significant environmental problems:

- Chemical pollution: chemicals added to plastics can be absorbed by humans and affect human health

- Ocean pollution: floating plastic waste can survive thousands of years in water and threaten sea animals when they ingest plastic debris

- Landfills: plastic packaging are hard to decompose adding burden on landfills

- Greenhouse gas emissions: 20% of global fossil-fuel consumption is expected to go into producing plastics by 2050 according to the International Energy Agency

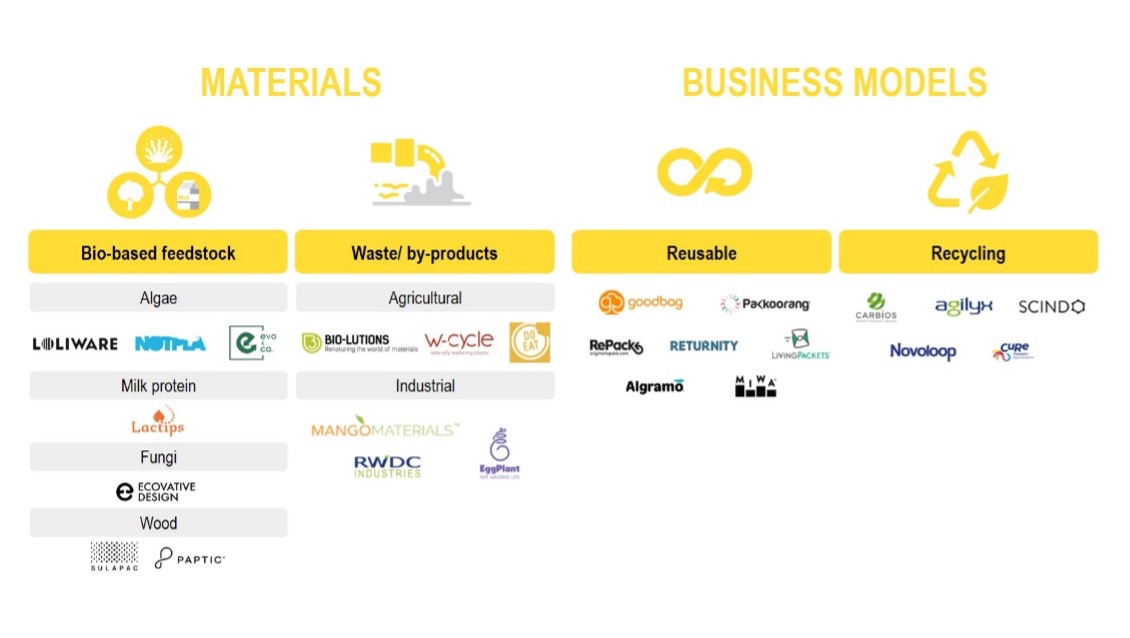

As e-commerce thrives, the demand for one-off plastic packaging will continue to rise. More sustainable options are needed to alleviate the impacts of one-off plastic packaging. The aim is to reduce the use of virgin plastics or extend the life of packaging with reusable formats and recycling. In this article, we look at innovations in materials and business models that address the problem.

Figure 1. Innovators addressing plastics packaging problem

BIO-BASED FEEDSTOCK

Bio-based feedstocks refer to materials that are wholly or partly derived from living matter. They are renewable agricultural and forestry raw materials but are not necessarily biodegradable.

Biodegradability depends on the molecular structure of the plastic rather than the raw materials used to make it. Some bio-based plastics can only break down in industrial composters with intense heat – if they end up in the sea, they will stay in the environment for as long as fossil fuel-based plastics do.

Yet, bio-based plastics help reduce carbon dioxide which is absorbed by plants during photosynthesis, a key difference from conventional plastics. Innovators are using various inputs from their in-situ environments to make bio-based plastics such as algae by those near the sea and wood by Nordic startups. Although bio-based plastics currently make up less than 1% of plastics produced worldwide, the production of bio-based plastics might compete with arable land for food production.

Figure 2. Mushroom® Packaging; Image courtesy of Ecovative

WASTE / BY-PRODUCTS

Alternatively, bio-based plastics can be made from waste or by-products from agricultural and industrial activities if land competition is a concern. This provides a secondary market for the otherwise destroyed crop residues. For example, Bio-lutions produces biodegradable packaging from crop waste collected at farms in India and W-Cycle processes bagasse from sugarcane fibres into packaging that claims to be liquid and oil-proof.

Industrially, waste methane released from waste treatment plants and landfills is a good source. For example, Mango Materials has been working with waste management facilities to convert methane into PHA biopolymers to make various plastics substitutes including flexible packaging. The goods created from the PHA biopolymers can fully biodegrade after use. As methane is a more potent greenhouse gas than carbon dioxide, this helps tackle global warming.

Figure 3. Waste management facilities; Image courtesy of Mango Materials

REUSABLE

Providing reusable packaging services is a way to cater to the e-commerce trend. Startups Repack and Returnity are just two examples. They develop durable reusable packaging and manage the return logistics for brands with reward programs to encourage customers to continue using their services. Another startup LivingPackets, makes a recyclable expandable box that features an E-Ink display, integrated camera and sensors that provide more security to their reusable boxes.

In addition to reusable packaging, a Chile-based startup Algramo, provides refill systems to allow customers to refill their cleaning products at affordable prices. Major consumer packaged goods companies such as Nestlé and Unilever are also experimenting their own refill programs – fuelling the development of reusable formats.

Figure 4. Smart packaging THE BOX; Image courtesy of LivingPackets

RECYCLING

While recycling plastic packaging is not yet as common as recycling plastic bottles especially for flexible packaging, it is a key step to enable a closed loop for materials. Currently chemical and biological recycling of plastics are better able to retain the quality of the recycled output.

LOOKING AHEAD

Some initiatives are underway to resolve the plastic packaging problem. Plastics have been a very useful material in the modern economy; finding materials with similar properties that are economically sound will take time. Yet the megatrend of moving away from fossil fuels will only drive the whole society to look for more solutions.

Some considerations that are important for tackling the plastic packaging problem include:

- Cost of alternative materials: Bio-based materials look promising, but packaging developed from biopolymers can be double the cost of those made with common plastic packaging.

- Education: Bio-based materials are not necessarily biodegradable and compostable does not necessarily mean home compostable. Clear labels and verification are important to educate the general public.

- Consumer incentives: In the absence of legislation, incentive mechanisms are needed to encourage consumers to embrace reusable formats and recycling.

As the traction continues, more is expected to be done for the above areas in the near future.

REFERENCES

1. World Economic Forum. ‘The New Plastics Economy Rethinking the future of plastics’: http://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf

2. ‘Naturally good? Searching for new bio-based raw materials for industry’: https://www.basf.com/global/en/media/magazine/archive/issue-6/naturally-good-searching-for-new-bio-based-raw-materials-for-industry.html

3. ‘Are Bioplastics Better for the Environment than Conventional Plastics?’: https://ensia.com/features/bioplastics-bio-based-biodegradable-environment/

4. ‘Scientists around the world are turning agricultural waste into food, packaging and skincare products’: https://www.greenbiz.com/article/scientists-around-world-are-turning-agricultural-waste-food-packaging-and-skincare-products

5. Packaging Europe. ‘Unilever launches its largest refill trial in Europe’: https://packagingeurope.com/unilever-launches-its-largest-refill-trial-in-europe/

6. ‘Nestlé pilots reusable and refillable dispensers to reduce single-use packaging’: https://www.nestle.com/media/news/nestle-pilots-reusable-refillable-dispensers-reduce-single-use-packaging