Reprocessing: The Art Of Repurposing

In any food production process, certain parts of the food, such as fruit peels and stems of vegetables, are discarded. Leftovers that cannot be sold in the food and beverage industry are also thrown away. In the past, some of these so-called “leftovers” were used for composting, but most were sent to landfills or incinerators. In response to this problem, many entrepreneurs, scientists and designers around the world have dedicated their time to researching and developing waste reduction solutions and have even granted food waste a second life, so that they can be upcycled to become more economically valuable foods or more useful materials and continue to be of service to mankind.

Have you ever considered that leftover bread can be used to make alcoholic drinks, that crop waste can be converted into sugar, that used coffee grounds can be turned into yarn for textiles, and that discarded grape skins from wine-making can be transformed into leather? These are not mere fantasies, for these solutions already exist by combining technology and creativity to reimagine the possibilities of how to reduce food waste.

(Image Courtesy: The Supplant Company)

About The Company

The Supplant Company is a developer of natural food ingredients intended to replace sugar in food products. The company's ingredients are plant[1]based, non-artificial, and non-GMO which are developed as a direct replacement for sugar, enabling food manufacturers to decrease sugar, increase fiber, and boost gut health.

“What we do is we make sugar from dietary fiber. In practice the fibers that we use are things that don’t make it into the food system and that’s core to the sustainability side of what we do. ”

Added sugars used in the food industry are strongly linked to the development of diabetes, obesity and heart diseases. To tackle this issue in a broad and innovative way, The Supplant Company has developed a brand-new blend of sugars made from plant fiber that not only tastes like sugar, but also has a low-glycemic response, and is lower in calories, prebiotic and gluten-free. We spoke with Tom Simmons, Founder & CEO of the company, also a carbohydrate scientist and a plant scientist, on how their approach may lead to some ground-breaking changes to the industry.

What are the main approaches of the supplant company?

What we do is we make sugar from dietary fiber. In practice the fibers that we use are things that don’t make it into the food system and that’s core to the sustainability side of what we do. We use agricultural side-streams, which are the majority of crops and plants that are grown around the world; corn cobs, corn stalks, rice straw, wheat straw, sugar cane stalks. These fibrous structural materials are in excess, the amount of them exceed the actual starch, carbs, our and sugar that are produced by these plants, and inside these materials they’re almost entirely made of fibers. Fiber are made of large chains of sugar that are bound together in complex ways which means they’re not digested — not absorbed — during human digestion. We take those long chains, and we have an enzyme-based process that breaks them down into short chains and those short chains then look molecularly — to a biochemist they look a bit more like sucrose — like cane sugar. Because they sort of look like cane sugar, they start behaving like cane sugar in food products when they’re broken down. And as they are fiber-derived they still retain fiber-based qualities when it comes to nutrition, so they behave more like fibre in your body. They’re low-glycemic like fiber is, pre-biotic like fiber is, low calorie like fibre is, despite the fact that they behave in cookies, cakes and candy like cane sugar does.

In what ways would this approach of converting crop waste into new sugars help tackle the problems related to the food industry?

Sugar cane plantations tend to be located in the tropics where tropical rainforests have to be torn down, so it not only is the number one source that leads to global biodiversity loss, it also accounts for a substantial proportion of carbon emissions globally.

The second issue that we hope to solve is on food waste. Most people think of food waste as “eat your vegetables before they go off ” but a huge part of food waste actually happens before crops leave the farm. It takes a conceptual frame switch for people to realize that the bulk of what comes off these crops is wasted already so we have to increase the efficiency of the current agricultural ecosystem. We have a growing population with limited real estate to grow crops from, so instead of trying to turn even more land into agricultural land, the alternative is to increase the efficiency of current crop production by better use of what has already been created. By upcycling crop waste into Supplant sugar, we are using what is already there, that is naturally produced all year round by our agricultural system with no negative impact on the environment.

Over the summer of 2021, the supplant company has partnered with Michelin star chef, Thomas Keller, to launch ice cream and shortbread using supplant sugars. How did this partnership come about?

The way it started was that one of the members of our team wrote a handwritten letter to Per Se in New York and managed to get the attention of one of Thomas’ chefs. Eventually we were invited to meet in front of Thomas, and we ew over to California to visit him in Napa. In addition to the Summer collaboration, we just launched in November two premium limited edition chocolate bars using Supplant sugars with Thomas, one being milk chocolate, and the other dark chocolate.

What’s next for the supplant company?

Consumers in the US will be able to ‑ nd Supplant inside US-based consumer products and partly we’ll be pushing those ourselves and partly working with partners who are already operating, as in selling the ingredient into existing products.

Anushka Purohit, one of the founders of the social enterprise startup Breer, estimates that more than 3,000 metric tons of food waste is discarded every day in Hong Kong, and that nearly half of that is perfectly edible bread that is about to expire. After noticing bakeries tossing unsold but still fresh bread into black trash bags every day, she and three students from the Hong Kong University of Science and Technology began to think about ways to rescue the bread. Soon, they discovered that the raw materials of bread and beer were similar, and so they came up with the idea of brewing beer from bread. When this proved successful, they created a craft beer company called Breer. In addition to running a business, they hope the company can contribute to reducing food waste.

What beer and bread have in common is that both contain barley malt, hops and yeast. The barley content of beer is generally 78%, which can be completely substituted with recycled bread. At the beginning, the Breer team didn’t know anything about brewing beer, but simply tried brewing it in their home kitchen, swapping barley for bread in the recipe and experimenting with different ratios of bread. Later, they took an online course to teach themselves brewing, and it took 3 to 4 months of trial and error before they finally succeeded in making beer. They participated in the Hong Kong region edition of the social innovation competition Enactus and won a prize with their product. After obtaining their startup capital, they sought cooperation with various local breweries, which further assisted them in improving their beer-making formula.

(Image Courtesy: Breer)

The Breer team said that the most difficult part of starting this business was not figuring out the brewing technology but finding retailers willing to provide them with leftover bread. With the help of the HKUST Entrepreneurship Centre, they eventually managed to find a bakery and restaurant chain willing to supply their leftover bread. Once collected, the bread needs to be sorted and its quality examined. Depending on the types and quantity of bread collected, the team can decide on the flavour. For example, the Breer team once came up with a recipe that included Mediterranean toast, potatoes and tomatoes to make a sweeter tasting beer. They have also collaborated with the Hong Kong Jardine Restaurant Group to brew beer using Pizza Hut's unsold and unused pizza crust. The two batches of “pizza crust ale” had a lighter taste than regular bread beer, and were offered for internal tasting at Pizza Hut as well as sold at the University of Science and Technology.

Breer is now collaborating with local breweries to produce two bread beer products: lager and pale ale. The first two batches totalling 500 liters were shipped out in October 2020 and sold at HK$20 per bottle. The response was overwhelming. Breer has already brewed over 6000 liters of bread beer, which is available for sale at online stores and certain restaurants in Hong Kong and Kowloon.

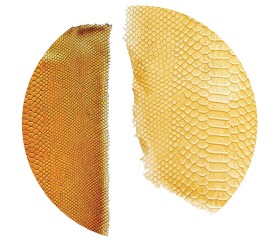

Vegea is a biomaterials startup company founded in 2016 in Milan. For the past few years, it has been dedicated to developing new eco-sustainable products that promote the integration between chemistry and agriculture. Its specialty is plant-based and even “food residue” products that substitute for non-renewable petroleum-based resources, and can be made into clothing, furniture, packaging, and automotive components. Vegea is already cooperating with various well-known brands, the most notable of which is its collaboration with H&M, which uses by-products of wine-making, such as grape skins, stalks and seeds discarded during wine production, and turns them into vegetal leather that are made into handbags and shoes. Furthermore, this vegan leather features a new dyeing process for fabrics that uses recycled polyester and waste coffee grounds.

(Image Courtesy: Vegea)

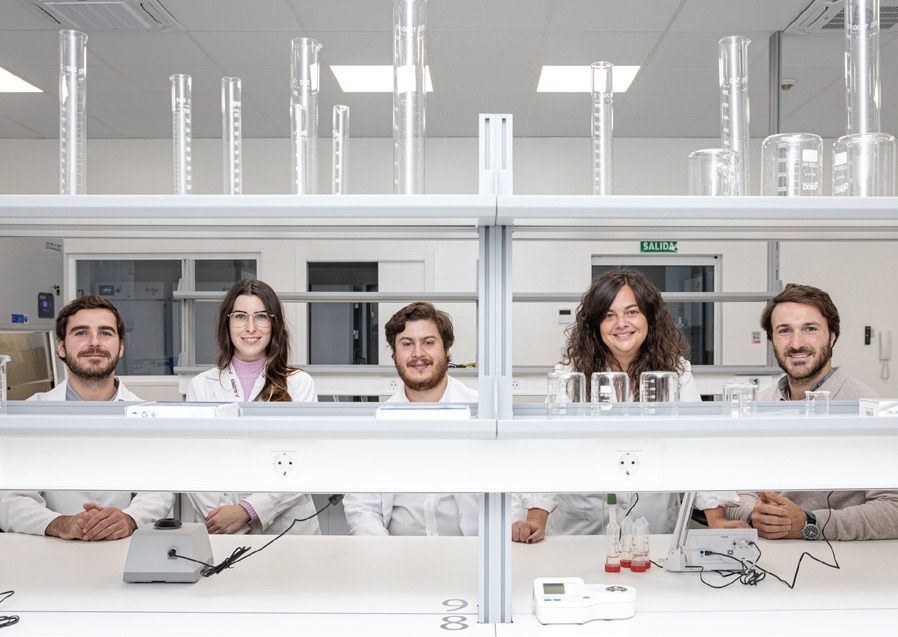

Based in Spain, MOA Foodtech is a B2B ingredient platform using biotechnology and artificial intelligence (AI) to transform food waste and food production process by-products into highly nutritional ingredients that can be used to make products such as meat and dairy alternatives. This solution not only tackles the food waste problem, but also helps to address the challenge of feeding a growing world population, without putting pressure on land while minimizing the negative impact of the existing food production system. These animal-free alternatives would contribute to stop deforestation, restore biodiversity and protect our planet.

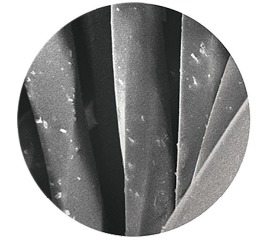

In addition to being utilized as deodorizer and fertilizer, what else can coffee grounds be used for? In 2008, Taiwan textile industry company SINGTEX Group developed a technology that turns coffee grounds into yarn, named S. Café. When we drink coffee, we only make use of 0.2% of the oils present in coffee beans, and we discard the other 99.8%. SINGTEX employs a low-temperature, high-pressure and energy saving process that transforms the 99.8% portion of coffee beans into yarn, thus harnessing coffee’s natural odor-absorbing, quick drying and UV reflecting properties. S. Café technology extracts the oils from coffee beans and turns it into breathable coffee membrane and coffee foam, which can reduce the use of petrochemical raw materials by more than 25%. On average, the company re-converts 10 tons of coffee grounds into resources every month, and so far, 1,200 tons of coffee grounds have been turned into resources.

(Image Courtesy: S. Café)

Tômtex is a 100% bio-based material using seashell waste, mushroom and co ee grounds as its key ingredients. The aim of the company is to replace both faux and animal leather with sustainable and economical substitutes. The Grand Prize winner of The Mills Fabrica “Techstyle For Social Good 2020”, International Student Online Competition Tômtex makes a 100% naturally degradable material, free of plastic and polylactic acid (PLA). It is a leather alternative created by Vietnamese designer Uyen Tran during the 2020 Bio Design Challenge, an innovative design competition, by utilizing food waste. She realized that clothes made of chemical fibers are difficult to decompose, so she started to look for alternative materials. In the process, she discovered that chitin found in food waste from seafood, such as shrimp shells, crab shells and fish scales is soft and tough, and can be made into leather that is pliant and easy to sew. When Tômtex reaches the end of its life, it can be reused or biodegraded. When it finally enters landfills, it can be completely biodegraded within a few months and become fertilizer for plants, thereby extracting the most value out of it.

(Image Courtesy: Tômtex)