- ABOUT US

- INVESTMENT FUND

- PARTNERSHIP SERVICES

- IMPACT INITIATIVES

-

SPACES

- HONG KONG

- Co-working space

- Event Space

- Prototyping Lab

- LONDON

- Co-working space

- Event Space

-

FABRICA X

- HONG KONG

- Campaign

- Events

- Online Store

- LONDON

- Exhibition

- Retail

- Subscribe

Fish farming, or aquaculture, is one of the fastest-growing food sectors worldwide, playing a crucial role in feeding a growing global population. Central to successful aquaculture is providing fish with a balanced diet that meets their nutritional needs for healthy growth, reproduction, and overall wellbeing. Traditionally, fishmeal and fish oil—derived from wild-caught fish—have been the primary ingredients in aquafeed. However, sustainability concerns and resource limitations, as mentioned in our last post, are driving innovation toward alternative protein sources. This time, we’ll explore fish nutritional requirements and dive into promising novel protein solutions, highlighting startups leading the charge in these areas.

Just like people, fish require a complex mix of nutrients, including proteins, lipids, carbohydrates, vitamins, and minerals. Different species have different needs, but generally, carnivorous animals have more exacting diets, requiring higher protein levels (40-50%) compared to herbivorous or omnivorous species (25-35%).1 Lipids provide concentrated energy and essential omega-3 fatty acids like EPA and DHA, vital for brain development and overall health. Seafood with a pink colour gets its pigment from its diet too, so salmon and shrimp also need carotenes to keep their colour bright.

Fishmeal and fish oil have been the go-to sources because they naturally contain a near-perfect balance of these nutrients, but due to their sustainability concerns, there is a search for alternative, sustainable protein sources that can replicate or even improve fishmeal’s nutritional profile.

Image: Shutterstock

1. Microbial protein, often called single-cell protein (SCP), is produced by cultivating microorganisms such as bacteria, yeast, or algae. These microbes grow rapidly and can convert waste streams into high-quality protein rich in essential amino acids.

The best developed of these technologies works just like brewing beer: you mix a source of carbs like starch or sugar into a tank to feed bacteria or yeast, and then let them grow until you have the cells you need. Startups like Microharvest are developing fast-growing, nutrient-dense microbes that can grow using agricultural waste. That way, not only are they reducing dependence on fishmeal, they’re also recycling materials that would otherwise go to waste. This technology is well understood, so it can be brought up to commercial scale quickly and cost-effectively.

Instead of using traditional sources of carbon, some companies are developing gas fermentation using bacteria that feed on greenhouse gases. Pulling carbon directly from the atmosphere and putting it into the food system can create ingredients whose carbon footprint is low or even negative! Calysta is using bacteria that eat methane from steel factories, while NovoNutrients is growing bacteria directly on carbon dioxide. Gas fermentation requires high-tech equipment to make sure the solid bacteria, liquid broth, and gaseous feedstock are all mixed together evenly, but when it’s done right, it can make high-quality carbon-neutral protein.

Aside from training them to grow better on waste materials, you can also grow them to make nutrients that improve animal health or provide specific functional benefits. Shrimp and salmon derive their colour mostly from the carotene astaxanthin, which they get from their diet. NovoNutrients and Knip are making aquafeed protein out of bacteria that produce astaxanthin, making them a one-stop shop for shrimp and salmon’s needs.

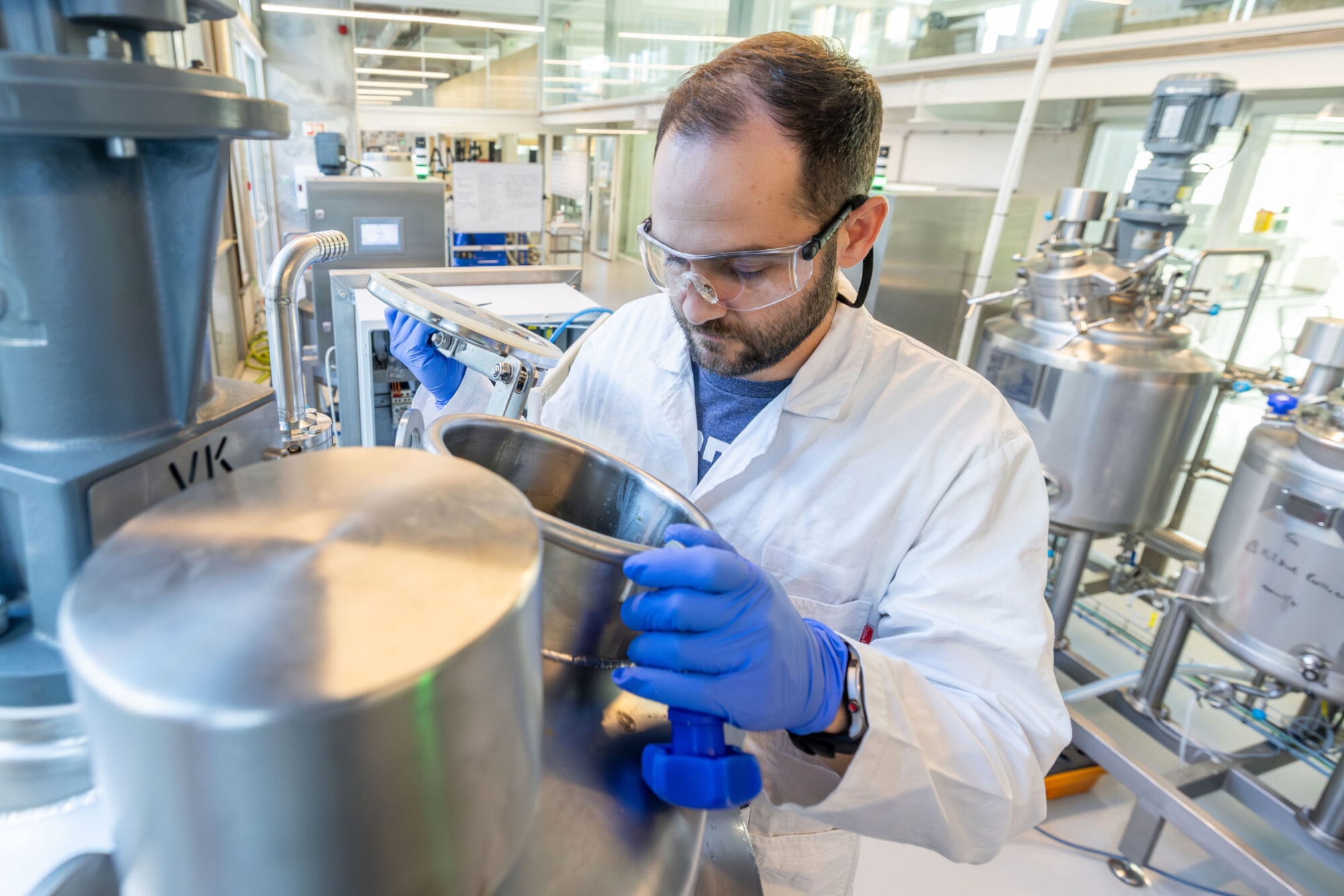

Image: MicroHarvest

2. Fungal proteins, derived from filamentous fungi or yeast, are gaining traction as sustainable feed ingredients.

Fungi can be grown on low-value industrial by-products with minimal water and land use, producing protein-rich biomass called mycoprotein. This biomass is rich in essential amino acids, vitamins, and minerals, making it an excellent fishmeal substitute.

A Finnish startup, Enifer, is commercialising a mycoprotein called Pekilo, first produced in the 1970s. Pekilo is cheap and versatile, growing on a variety of industrial side streams, including from Finland’s paper and timber industries. It was ahead of its time in the ‘70s, but now might be its time to shine.

Image: © Iiro Muttilainen

3. Insect protein is also a good alternative for fishmeal, since insects are nutritionally similar to the diets many fish eat in the wild.

The most common insects for food are black soldier fly larvae (BSFL), mealworms, and crickets. Insects can provide a nutritionally dense food source with minimal land and water use, although there have been some concerns about insect feed competing with existing food and feed supplies.2

The companies Innovafeed and Ynsect pioneered BSFL farming, scaling up to produce insect meal for pet food and aquafeed. However, insect farming had never been industrialised before, so they hit some stumbling blocks while scaling up their production facilities. New innovations are always being developed to overcome these challenges.

Image: picture via Canva.com

The shift from traditional fishmeal and fish oil to alternative proteins is essential for sustainable aquaculture growth. Microbial and fungal proteins offer scalable, circular solutions that can be tailored to fish’s nutritional needs. Insect proteins provide a natural, efficient protein source closely aligned with fish dietary habits. Further development in these fields and exciting new technology working with algae or plankton are quickly making these novel ingredients viable alternatives to fishmeal. Together, these innovations promise to reduce environmental impacts, improve feed security, and support the global demand for seafood in a more sustainable manner.

Image: picture via Canva.com