- ABOUT US

- INVESTMENT FUND

- PARTNERSHIP SERVICES

- IMPACT INITIATIVES

-

SPACES

- HONG KONG

- Co-working space

- Event Space

- Prototyping Lab

- LONDON

- Co-working space

- Event Space

-

FABRICA X

- HONG KONG

- Campaign

- Events

- Online Store

- LONDON

- Exhibition

- Retail

- Subscribe

Circularity — Fueling Up a Sustainable Economy

The industry has been looking for solutions to recover

from the pandemic. Perhaps a circular economy can help

the industry bring about a profitable and sustainable future

by reducing waste and fully utilising resources. McKinsey

conducted a survey during the pandemic, which revealed that

most consumers consider brand value above all when making

purchasing decisions, creating a golden opportunity for the

industry to transition to a circular economy.

(Image Courtesy: Unsplash, H&M Foundation, Algaeing, Fairbrics, Galy, Unmade, Unspun, Zer Collection, Olio, Reflaunt, Rent The Runway)

Read More

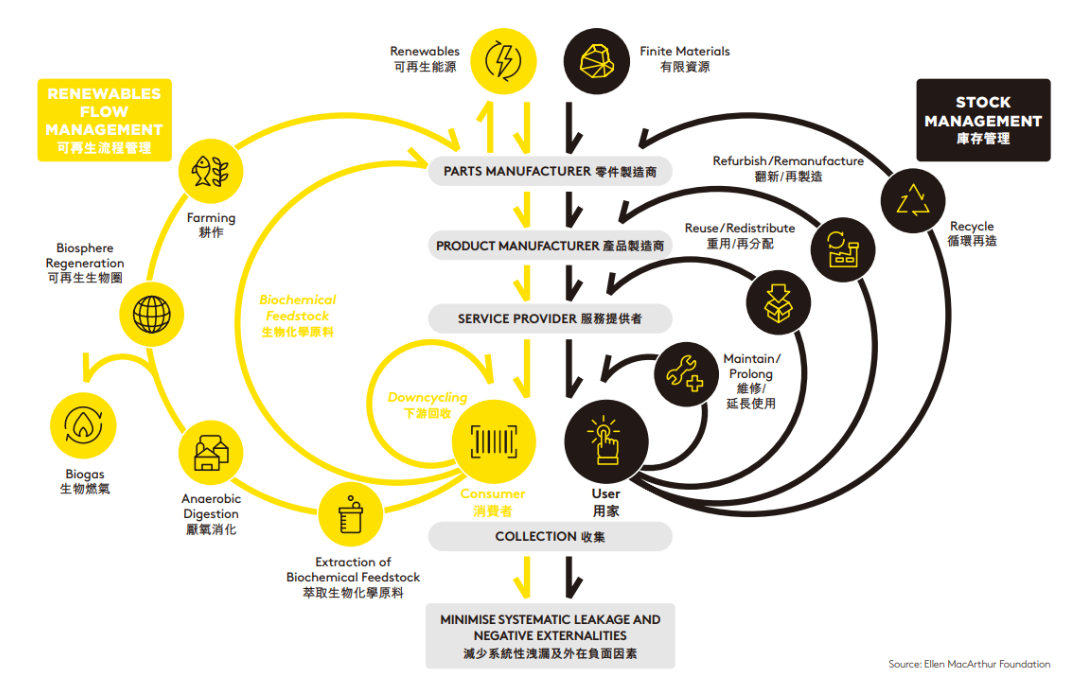

Unlike the ‘take-make-waste’ linear consumption model, circularity encourages both producers and consumers to co-create a regenerative system that maximises the value and life span of products to eliminate waste and pollution in the first place.

The United Nations found that garment manufacturing accounts for 10% of global carbon emissions, urging the industry to innovate manufacturing processes over the years. By using renewable energy and sustainable fabrics, denim factories can save up to 53% electricity, 88% of chemicals and 99% water, enabling the industry to be eco-friendly and resource-effective at the same time.

Circularity also creates great value for the economy. PlasticsEurope reported that over 9 million tons of plastic were converted into new materials in 2019, creating 700,000 new job positions every year in response to the growing market. Meanwhile, given the increasing awareness toward sustainable fashion, the second-hand clothing market is expected to be valued at 64 billion USD in 2024. In addition, recycling and reusing keeps materials circulating in the market, allowing the industry to secure sufficient supply and build up resilience to brace for future crises.

However, achieving circularity must be a collaborative effort — from raw materials and product design to recycling post-consumer waste — it requires concerted efforts from all supply chain players. In the next few pages, we will introduce startups in different fields that embrace circularity with their cutting-edge solutions and business models.

Circularity at a glance

Algaeing

Founded

2018

Headquarters

Beit Yitzhak, Israel

Algae has been seen as a natural replacement to plastic as it proliferates rapidly and captures CO2 while growing, making it a highly efficient, bio-degradable and carbon-negative material. The Israeli biotech startup Algaeing uses algae to produce non-toxic pigments and textile fibres. While industrial dyes and synthetic fibres can irritate sensitive skin, Algaeing’s algae-based products can nourish human skin as it is rich in vitamins and antioxidants.

Fairbrics

Founded

2019

Headquarters

Clichy, France

Founded by chemists Benoît Illy and Tawfiq Nasr Allah, the startup uses air instead of petroleum to produce polyester. They use molecular chemistry to transform carbon dioxide in the atmosphere into small pellets, which can be spun into polyester yarn. The whole process does not generate any greenhouse gases and even captures CO2 in the air, reshaping the future of synthetic fibres with a carbon-negative solution.

Galy

Founded

2019

Headquarters

Boston, US

Traditional cotton farming takes 20,000 litres of water to yield 1kg of cotton, not to mention the toxic chemicals used to control pests. Galy has developed a lab-grown solution by cultivating cotton cells in glass vessels, which grows ten times faster and uses 80% less water than the conventional farming method, providing the textile industry with a more sustainable alternative to regular cotton.

Unmade

Founded

2014

Headquarters

London, UK

Unmade is an end-to-end cloud-based platform that connects brands and retailers to their customers. It allows fashion brands to create template designs using its online platform, while customers can personalize the products based on their preferences. Once the company receives customers' orders, they will start producing digital patterns to manufacture the final products. Apart from ready-to-wear, the startup has collaborated with Rapha to customise sportswear for professional cycling teams.

unspun

Founded

2015

Headquarters

San Francisco, US / Hong Kong

Fabrica incubatee unspun is a robotic company that develops a 3D weaving technology to enable automated customization. The startup aims to reduce 1% of global carbon emissions for now. Customers can experience the concept by customising a pair of jeans and scan their bodies using their mobile phones, with the body scanning process taking just 30 seconds. Its algorithms will then generate a digital pattern that perfectly fits the customer’s body for production.

Zer Collection

Founded

2017

Headquarters

Barcelona, Spain

20% of fabric ends up as waste during the production process, Huff Post reports. Founded by two fashion designers with technology backgrounds, Zer Collection is a fashion brand that creates zero-waste clothing by adopting 3D printing technology. It allows the brand to control the size, shape, elasticity and thickness of the fabric, avoiding redundant scraps created in the cutting room.

Olio

Founded

2015

Headquarters

London, UK

OLIO is a mobile app that redistributes surplus food generated by food businesses to the community. Non-industry users can also share leftovers with their neighbours by simply creating a listing on the app. Users can share other consumer goods like cosmetics and pet food as well. Over 2.6 million users have downloaded the app, and nearly 10 million portions of food have been rescued.

Reflaunt

Founded

2017

Headquarters

London, UK

Reflaunt is a platform that empowers the fashion industry to resell fashion items. Luxury brands, retailers or shoppers can use the platform to buy or resell excess inventory or second-hand items. Every item sold on the platform is checked and shipped to the end-user by Reflaunt, ensuring all pre-loved items are handed over to the next owner in good condition.

Rent the Runway

Founded

2009

Headquarters

New York, US

Rent the Runway is a membership-based platform that gives users access to thousands of fashion items through a rental model to encourage consumers to reduce fashion waste. Users can rent a garment for one-time use or subscribe to a collection of clothes on a weekly basis. All used clothes will be steam-cleaned using a fragrance-free and biodegradable detergent, making sure each piece looks brand-new when passed on to the next user.